Metallurgical and Materials Engineering

Computational Fluid Dynamics (CFD) simulations are essential tools in the metallurgical and materials engineering industries. They are used to analyze, model, and predict fluid flow, heat transfer, and other physical phenomena in processes involving molten metals, solidification, and materials manufacturing. Here's a breakdown of the purpose, applications, and benefits of CFD simulations in these industries:

Purpose of CFD Simulations in Metallurgical and Materials Engineering:

Process Optimization: CFD simulations enable engineers to optimize processes like casting, forging, and welding by visualizing fluid dynamics and thermal distribution. This helps in improving efficiency and product quality.

Predicting Behavior: CFD allows for the prediction of fluid flow patterns, temperature gradients, and phase changes in materials. This is crucial in understanding how molten metals solidify or how certain materials respond to mechanical stresses.

Design Improvement: It helps in improving the design of equipment such as furnaces, molds, and reactors by simulating various scenarios, which reduces the need for expensive physical prototypes.

Troubleshooting: CFD simulations can pinpoint where issues like poor heat distribution or flow irregularities occur, aiding engineers in identifying problems in existing systems or processes.

Applications of CFD Simulations in Metallurgical and Materials Engineering:

Casting Process:

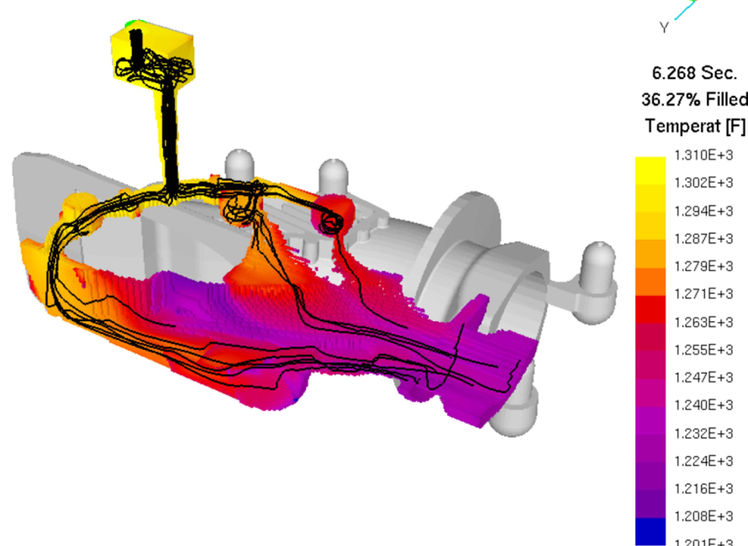

Mold Filling: CFD is widely used to simulate the mold filling process in casting operations, such as sand casting, investment casting, or die casting. It helps in predicting the flow of molten metal into molds, identifying areas prone to defects like porosity, air entrapment, or incomplete filling.

Solidification: CFD is used to model the cooling and solidification process, enabling engineers to predict the microstructure and mechanical properties of the final casting.

Heat Treatment Processes:

Temperature Distribution: In processes like annealing, quenching, or tempering, CFD simulations help predict the heat transfer and temperature distribution in materials, optimizing time, temperature, and cooling rates to achieve desired material properties.

Furnaces and Reactors:

Flow Simulation: CFD is used to simulate the air, gas, and heat flow in blast furnaces, electric arc furnaces, and other types of reactors. This helps to design more efficient systems and reduce energy consumption.

Combustion Modeling: In furnaces, CFD can model the combustion process, optimizing fuel usage, minimizing emissions, and improving the quality of the materials being produced.

Welding and Joining:

Heat Affected Zones (HAZ): CFD simulations help to predict and control the thermal cycles during welding, ensuring optimal weld quality by preventing issues like distortion or cracking.

Flow of Molten Material: In welding, CFD can simulate the flow of molten metal and predict the formation of weld beads and the heat-affected zone.

Powder Metallurgy:

Flow and Sintering: CFD simulations are used to predict the behavior of powders during sintering and compaction processes, helping to optimize the density, porosity, and mechanical properties of the final material.

Additive Manufacturing:

Layer Deposition and Cooling: In metal 3D printing, CFD helps simulate the cooling and heat distribution during each deposition layer, preventing issues like warping or cracking due to thermal gradients.

Benefits of CFD Simulations in Metallurgical and Materials Engineering:

Cost Reduction:

CFD simulations reduce the need for costly physical testing by allowing virtual trials. Engineers can optimize designs and processes without having to physically create every iteration of a system.

Process Efficiency:

By understanding the fluid flow, heat distribution, and material behavior in simulations, companies can enhance the efficiency of their processes. This includes reducing energy consumption, minimizing waste, and improving material yield.

Quality Control and Consistency:

CFD helps ensure uniform quality in final products by predicting and controlling variables like cooling rates, temperature gradients, and fluid flow. This results in fewer defects and more reliable, consistent products.

Enhanced Product Performance:

By using CFD simulations to predict how materials behave under different conditions, manufacturers can design products with improved properties, such as strength, ductility, and resistance to wear and corrosion.

Faster Time-to-Market:

Simulation reduces the time spent in trial-and-error testing. By allowing virtual prototyping, CFD enables engineers to iterate on designs more quickly, leading to faster development cycles.

Better Decision-Making:

CFD offers valuable insights into complex physical phenomena that might be difficult or expensive to measure in real life. This enables engineers and decision-makers to make informed choices based on accurate data.

Environmental Benefits:

Optimizing furnace designs and metal processing techniques with CFD can help reduce energy consumption and emissions, making manufacturing processes more sustainable.

Improved Safety:

By simulating hazardous scenarios, such as the eruption of molten metal or excessive temperatures in certain areas, CFD can help design safer systems and processes in the metallurgy industry.

Conclusion:

CFD simulations are a powerful tool in metallurgical and materials engineering, offering significant benefits in terms of process optimization, cost reduction, quality control, and safety. They enable manufacturers to innovate, improve efficiency, and produce higher-quality materials while minimizing waste and environmental impact. These simulations are integral for advancing the industry, as they provide a more precise and data-driven approach to designing and controlling metallurgical processes.

.png)